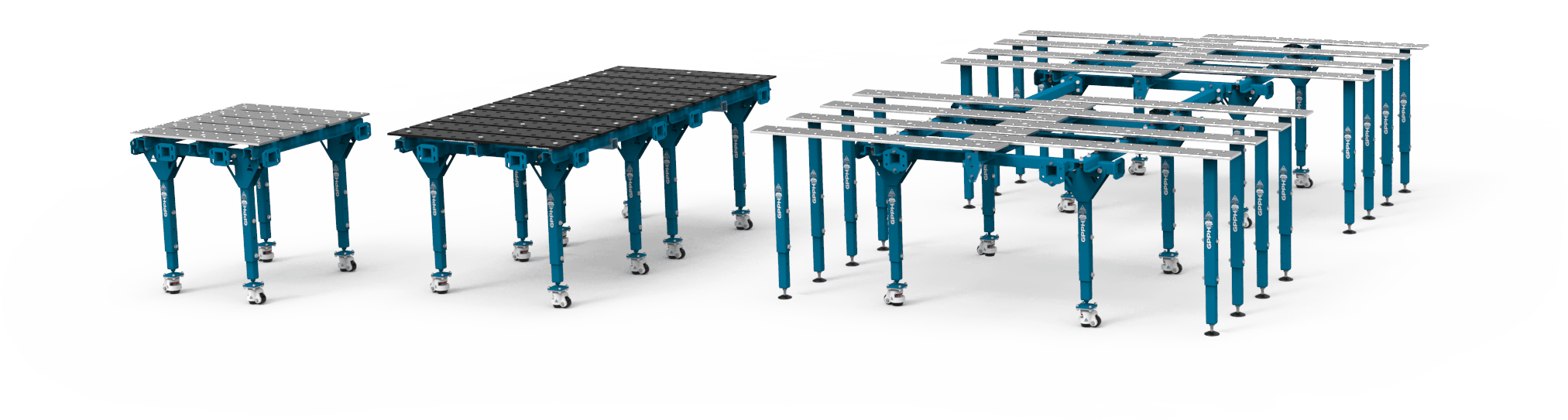

Do you dream of a tool that adapts to your needs and makes the most demanding projects possible? Our modular tables are the answer to your expectations!

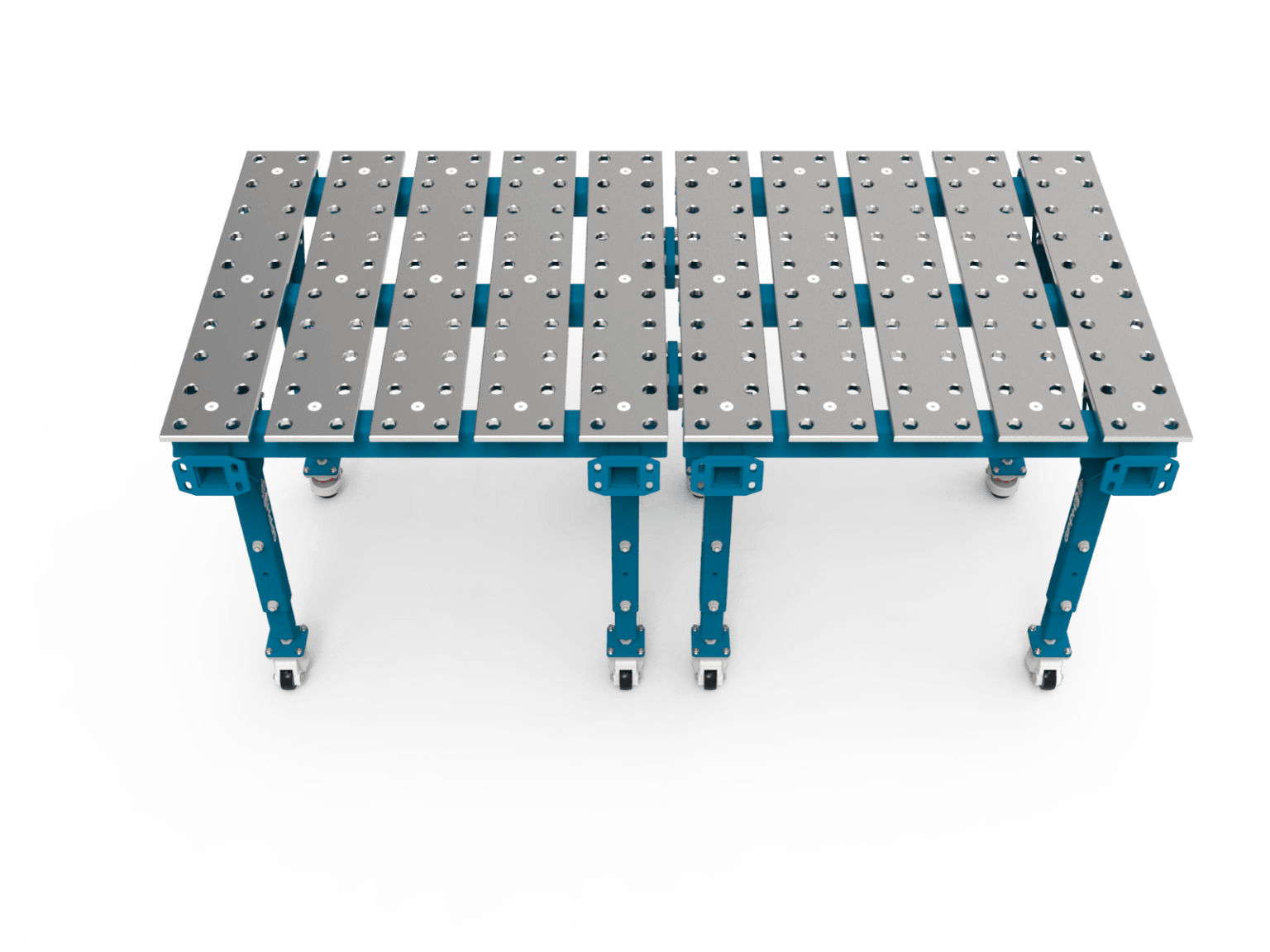

Discover unlimited possibilities with the modularity of our tables. This series of GPPH welding tables will allow you to create unique configurations that best suit your production requirements. The tops of the modular tables are made up of milled, sliding panels 15 mm thick, and by adjusting their surface you will achieve perfect flatness. They are made with a ⌀28 mm hole system in a 100x100 mm grid.

The modular tables have wheels with a foot in the base legs, with a load capacity of 250 kg per leg. The extending versions of the modular tables have adjustable supports in the extra legs. The height of the tables can be adjusted between 850 mm and 1150 mm, P=50 mm.

In order to obtain a larger working area, the tables can be combined with each other. As an option, you can also purchase side plates.

We have designed this series in a modular way, allowing you to easily adapt and expand your welding station to suit your specific needs. This allows you to create individual configurations that best suit your production requirements.

Choose the GPPH series of modular welding tables and experience the advantages of an advanced and functional tool. Increase the productivity, precision and quality of your welding work with a focus on quality, innovation and professionalism!

The applications for GPPH modular welding tables are endless! Thanks to their versatility, robustness and innovative design approach, they are widely used in various industries and production processes. Here are some of the main applications for GPPH modular welding tables:

These are just some examples of the applications of GPPH modular welding tables. Their flexibility and advanced technical features make them the perfect choice for professional welders and production halls. If you are looking for a tool that meets your requirements and allows you to achieve the highest quality welding work, GPPH modular tables are the answer!

Modular welding tables are versatile tools for professional welders and production workshops. They are characterised by their modular table top design, robust workmanship and easy expandability. They will help you achieve the ideal position for welding, grinding and cutting, resulting in higher quality and efficiency.

GPPH Modular Welding Tables are divided into:

Each of our tables is made with the utmost attention to detail, ensuring that they are not only robust, but also adjustable in height. You can also combine tables to create a larger work surface, and optionally purchase side plates to further optimise your workstation.

Choose GPPH modular welding tables that are not only functional, but also adaptable to different dimensions and forms of work. Our tables are the key to better organisation and efficiency in your production. See for yourself how our tables can revolutionise your welding work.

The GPPH Modular Welding Tables are available in two top plate designs:

Both tabletop material options - S355J2+N and treated tool steel - are the choice of robustness, durability and exceptional resilience for your welding station. At GPPH, we know that quality is the key to success, which is why our modular tables are carefully crafted with the utmost attention to detail to meet your highest expectations.

The tops of the modular tables are made up of milled, sliding plates 15 mm thick, and by adjusting their surface you will achieve perfect flatness. They are made with a ⌀28 mm hole system in a 100x100 mm grid, allowing for easy and flexible attachment of tools and accessories. They have milled and chamfered holes for easy tool mounting, making your workstation organisation even more efficient.

GPPH modular tables are compatible with PRO series tools, making the use of our tables and accessories even more efficient. In addition, the design of our modular tables allows you to increase the number of attachment points for tools in the gaps between the tabletop plates, resulting in increased ergonomics for your work.

GPPH modular tables are equipped with wheels with feet in the base legs, with a load capacity of 250 kg per leg. The fold-out versions of the modular tables feature adjustable supports in the extra legs, which ensures stability and comfort when working. An additional advantage is that the height of the tables can be adjusted from 850 mm - 1150 mm to suit your preferences.

In order to obtain a larger working area, the GPPH modular tables can be combined with each other. In addition, you can also optionally purchase side plates to increase the functionality of your welding station. Choose a professional solution that provides you with a stable and sturdy basis for excellent results - GPPH modular tables, created with your satisfaction in mind.

We provide a variety of dimensions for modular welding tables to meet your production needs.Single tables are available in three standard dimensions: 1000x1000, 1200x1200 and 1600x1500. If you need a folding single table, we offer versions with dimensions: 1770x1000, 2170x1200 and 2670x1600.

For double tables, we offer the following dimensions: 2000x1000, 2400x1200 and 3200x1500. And for those who need a larger working area, we have large area sets with dimensions: 2630x1770, 3030x2170 and 4000x2670.

Choose the right configuration that best meets your production requirements and provides an efficient solution for your welding process.

Our modular welding tables have a system of holes ⌀28 mm in diameter, arranged in a 100x100 mm grid. This arrangement of holes enables tools and accessories to be mounted precisely and quickly anywhere on the table top.

With this hole grid, you can easily customise your workstation configuration to suit your individual needs. The ⌀28 mm hole system allows you to use a variety of fixtures that allow you to precisely position workpieces for welding, grinding, or other metalworking.

It is worth mentioning that the ⌀28 mm holes in the 100x100 mm grid on our modular welding tables are carefully milled and chamfered. This detailed workmanship brings a number of advantages to the tool assembly process.

The milled and chamfered holes ensure a perfect fit and smooth edges, which makes it easier to mount various components on the table top. As a result, tools and accessories are positioned in a more precise and stable manner, resulting in higher quality welding and metalworking work.

In addition, the milled and chamfered holes make the tools less vulnerable to damage during assembly and disassembly. This increases the life and durability of both the tools and the table top itself, resulting in a longer service life for the entire welding station.

The legs on GPPH modular welding tables are not just supporting elements, but a key factor in the stability and versatility of these tables. Our legs have been carefully designed and manufactured to ensure the highest quality and reliability in everyday use.

The performance and functionality of the welding tables has been optimised to the maximum by the possibility to adjust the height of the legs between 850 mm and 1150 mm. This allows the table to be adapted to the user's individual preferences and the requirements of the specific welding job. This flexibility allows the table to be optimally positioned, which is crucial for the welder's comfort and convenience when working.

In addition, the legs of the GPPH modular tables have been fitted with sturdy wheels that allow the table to be easily moved around the workplace. This is an invaluable advantage, especially in large halls where tables must be adapted to changing production needs and different workstations.

Thanks to careful craftsmanship, intelligent design and advanced solutions, the legs on GPPH modular welding tables provide a solid and stable base. Adjustable leg heights and mobility on castors allow the table to adapt smoothly and efficiently to different applications, resulting in excellent welding results and productivity. It is a reliable tool for production workshops and welders who focus on quality, functionality and professionalism.

Additional accessories such as side plates are an important part of the functionality and versatility of GPPH modular welding tables. The side plates are a practical addition that greatly expand the tables' capabilities and use, adding valuable functions.

Thanks to the side plates, it is possible to make even more optimal use of the work surface of the welding tables. Like the table tops, the side plates have milled and chamfered holes, which makes it easier to mount tools, such as extensions, on them to increase the work surface.

The additional side plates provide the perfect place to mount the mobile tool shelves that are needed in the welding and metalworking process. Thanks to them, all tools and materials are always at your fingertips, increasing your working comfort and allowing you to carry out your tasks smoothly.

The side plates offer a wide range of possibilities to expand and adapt the table to specific production requirements. They are a unique solution for professionals who value flexibility and versatility in the workplace. They allow optimum use of the working space, ensure the stability and functionality of the table, and make work easier, allowing you to focus on efficient and precise welding and metalworking. This is a reliable tool for professionals who strive for excellent results and the highest quality of work.

Our modular tables made from S355J2+N material treated with nitriding and oxidation are the solution for professionals who demand the highest quality and durability. The nitriding treatment process increases the hardness of the table surface, making it resistant to scratches, abrasion and damage.

Oxidation, on the other hand, gives the table surface excellent corrosion resistance, making it not only durable but also perfectly suited to various working conditions.

Modular tables in nitrided and oxidised tool steel are the assurance that your workstation will maintain its excellent qualities for a long time, even under intensive use. The resistance to damage and corrosion makes this choice ideal for demanding applications in welding and industrial workshops.

Choose our modular tables and you will see that this is an investment in the reliability and durability of your welding station. Give your projects a stable and durable base - bet on quality and innovation at GPPH!

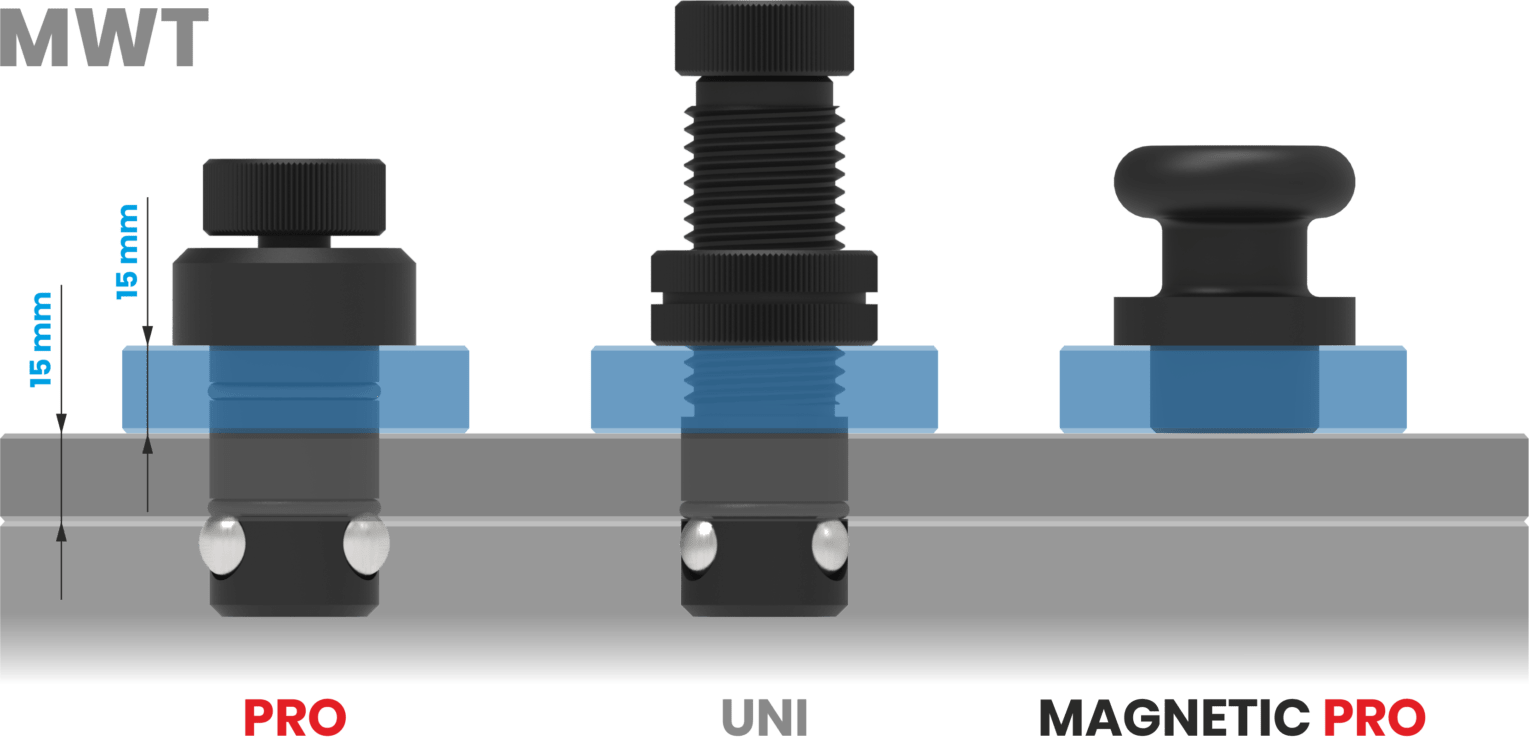

Fast assembly bolts are key tools that ensure fast and secure mounting on our modular welding tables. At the modular welding tables, you will use the PRO series of fast assembly bolts, ideal for fixing PRO series tools.

In our range you will find different types of fast assembly bolts, such as magnetic assembly bolts, classic quick-mounting assembly bolts and adjustable universal assembly bolts. Each has its own application, allowing you to optimise the tool assembly process and achieve the best results.

If you need to mount tools in different locations on welding tables, magnetic assembly bolts are the ideal solution. They give you complete freedom and make maximum use of the available work surface.

On the other hand, if you want fast and secure tool mounting, the classic quick-mounting assembly bolts are perfect. They ensure quick tool attachment and maximum work efficiency.

Adjustable universal assembly bolts are suitable for clamping tools of different thicknesses. In addition, they allow three tools to be clamped simultaneously at a single point and are ideal for supporting welded spatial structures.

Forget the hassle of tool assembly. Our PRO quick-assembly arbors combined with our modular welding tables guarantee perfect use of your workstation! Discover how many benefits and conveniences our solution will bring you.

Discover how the milled tools in the PRO series interact with the modular welding tables, enabling you to realise your designs quickly and precisely. Discover a new level of efficiency in your work!

Work efficiently and precisely when creating flat and spatial structures with our milled tools. Choose ready-made tool sets for modular welding tables or compose your own set and gain advanced solutions.

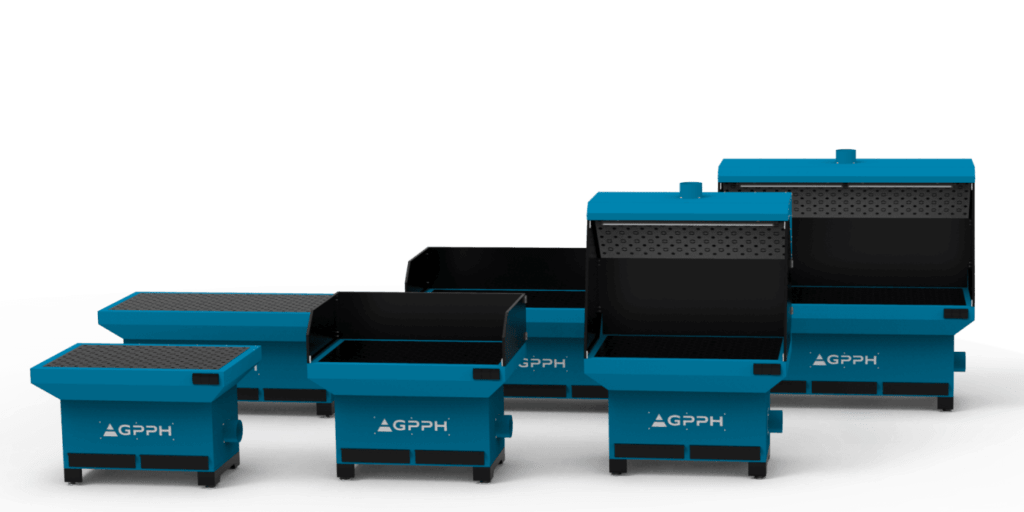

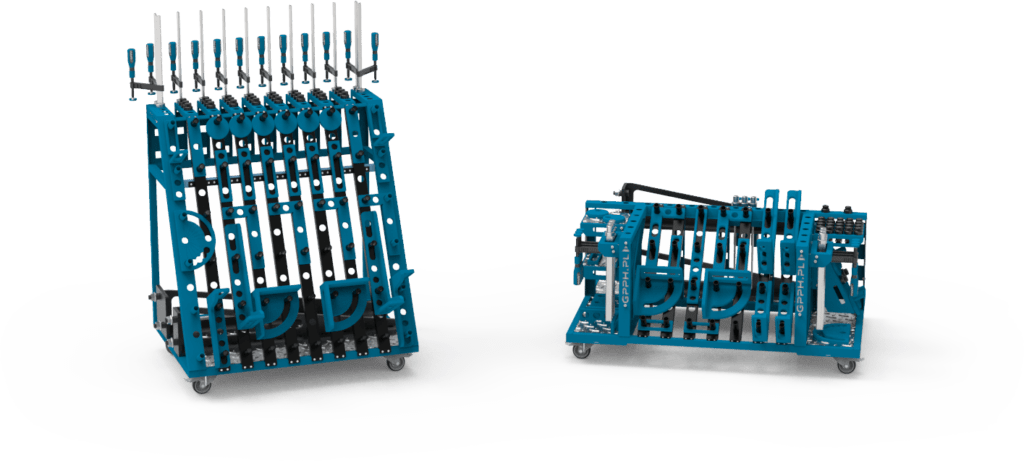

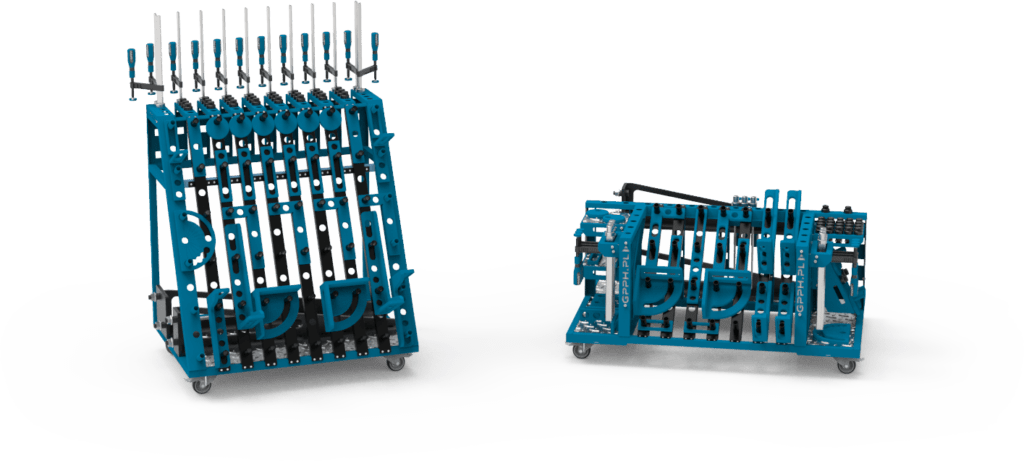

Forget about clutter and lost time! Our tool trolleys are the perfect solution for your workplace. Stay tidy, keep all your tools within easy reach and focus on working efficiently.

Forget the chaotic search for tools amongst the growing clutter. Our small tool trolley has been carefully designed to keep all your essential tools and accessories within easy reach.

How about our large tool trolley? This is the solution for those who need even more space and want to accommodate even the most demanding tool kit. Not only does it offer capacity, it also offers intuitive organisation of your GPPH tools, keeping them organised and easily accessible.

GPPH tool trolleys are not just an accessory, they are a way to improve the quality of your work. They will make your workplace a well-organised zone and give you an edge in organisation and efficiency. At GPPH we know that order matters - check it out for yourself! Choose GPPH tool trolleys and discover how tidiness improves the quality of your work!

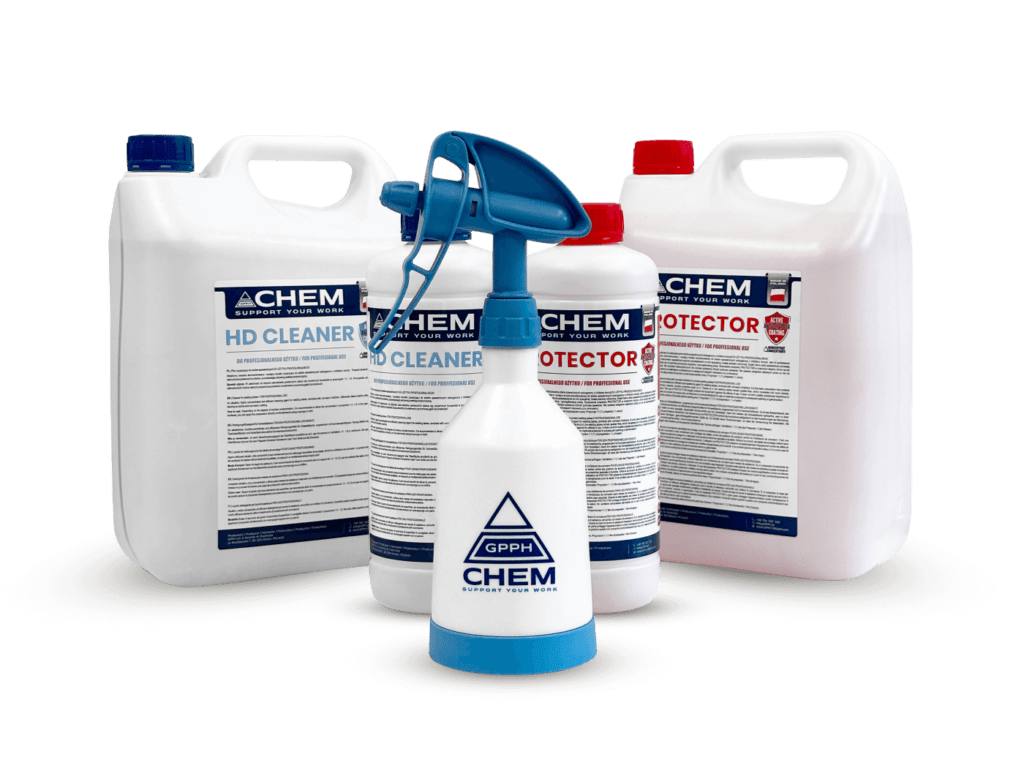

Let your welding table maintain its performance for many years. GPPH CHEM chemicals will help you to properly care for and protect it so that it always remains at the highest level.

Protector is an anti-scratch concentrate that forms a durable and protective film to protect against welding spatter and corrosion. HD Cleaner, on the other hand, is a highly concentrated cleaning fluid that effectively removes tough dirt, leaving the table surface in impeccable condition.

Thanks to GPPH CHEM's professional products, your grinding and welding station will be in excellent condition, contributing to greater working efficiency and long-lasting use of this reliable equipment. Provide your stand with proper care and enjoy its durability and high quality for many years!

| Copyright GPPH S.C. © 2024 |

Achieve perfect organisation with our small tool trolley that allows you to have all your tools within easy reach.

Need even more capacity? Our large tool trolley will accommodate even the most extensive tool sets. Everything will be organised and ready to use.

Work efficiently and precisely when creating flat and spatial structures with our tools and accessories for welding tables.

Choose ready-made tool sets or compose your own set and gain an improvement in your daily work.

Welding table care is the key to its long life. Choose GPPH CHEM professional chemicals and enjoy effective work for many years.

Achieve perfect organisation with our small tool trolley that allows you to have all your tools within easy reach.

Achieve perfect organisation with our small tool trolley that allows you to have all your tools within easy reach.

Need even more capacity? Our large tool trolley will accommodate even the most extensive tool sets. Everything will be organised and ready to use.

Our innovative grinding and welding stations effectively eliminate dust and gases generated during grinding and welding work. They work together with an extractor or filter fan, effectively improving the air quality around the workstation.

They will help you achieve greater efficiency in your work, focusing on excellent results.